Case 1 Matching product quality in High Gravity beer fermentation

The issue

One of our clients needed to employ beer fermentation recipes at different wort gravities without affecting product quality in order to be able to respond to varying demand in beer sales without the need for investments in fermentation tanks capacity.

| Our approach We offered to use a two track approach: -Make an overview of recipe parameters that affect product quality in response to changes in wort gravity using statistical analysis and modeling of available historical data -Extrapolate the effects found in the historical data to design and test new fermentation recipes fitting the range of wort gravities required. The project was carried out on site in collaboration with the local head brewer and brewing operators. |

| Our solution Our approach resulted in optimized fermentation recipes for different wort gravity settings that enabled the brewery to smoothly follow (seasonal) variation in product demand. Also, suggestions were made to improve parts of the installation to enable even more flexibility in production capacity. |

Case 2 Taking TPM to a higher level

The issue

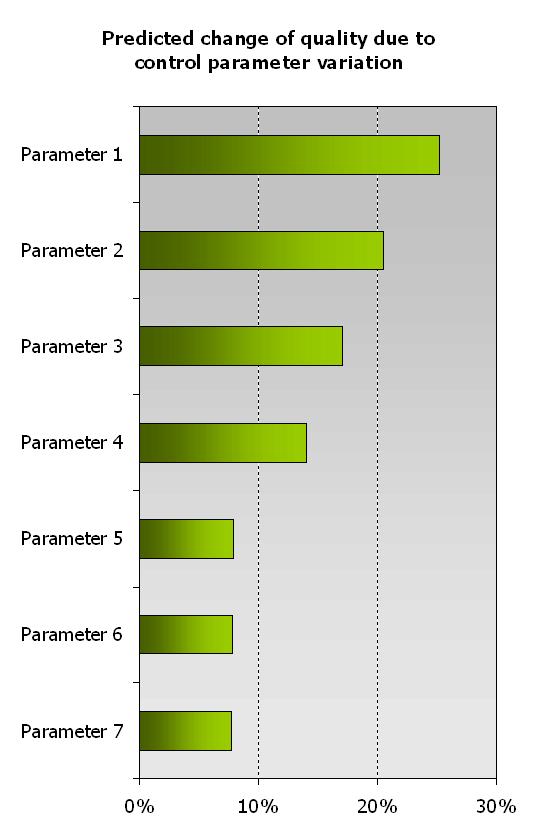

One of our clients was interested in reducing product quality variations to a minimum. Using traditional TPM methodology, a large number of potential causes of variation was found. Tackling all of these issues would take a substantial amount of time. The question was: ‘Is there a way to select the issues that will have the most effect for improving product quality?

| Our approach After consultation with the client we decided to use the following approach: Create a list of potential causes of variation in product quality and determine the capability for each of the control parameters. In stead of starting to improve the parameters with the lowest control capability, we determined objectively which of the parameters had the most effect on product quality, first. Making a Pareto of the ‘effective control capability’ of the several process parameters, clearly pointed out the improvement strategy. The project was carried out on site in collaboration with local process technologists and operators. |

| Our solution Our approach resulted in a substantially improved and sustainable control of product quality, in a few months time. |